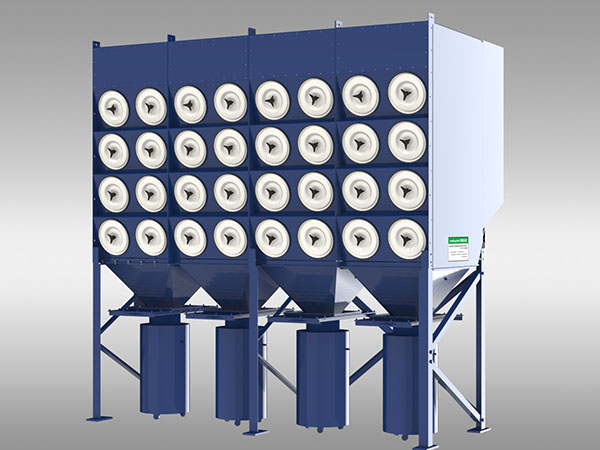

Cartridge Boodhka ururiyaha

Sharaxaad Gaaban:

Qaab dhismeedka kartoonada tooska ah ee shaandhada waxaa loo isticmaalaa si loo fududeeyo nuugista boodhka iyo ka saarista boodhka; iyo sababta oo ah walxaha shaandhada ayaa ruxaya inta lagu jiro boodhka laga saarayo, nolosha kartoonada shaandhada ayaa aad uga dheer tan bacda shaandhada, qiimaha dayactirkuna waa yar yahay.

Dulmar

Nooca kartridge-ka boodhka ururiyaha waxa kale oo loo yaqaan majaladda nooca boodhka ururiyaha ama kartridge-ka nooca shaandhada. Tilmaamaha ugu muhiimsan waa sida soo socota:

1.Qaab dhismeedka kartoonada tooska ah ee shaandhada waxaa loo isticmaalaa si loo fududeeyo nuugista boodhka iyo ka saarista boodhka; iyo sababta oo ah walxaha shaandhada ayaa ruxaya inta lagu jiro boodhka laga saarayo, nolosha kartoonada shaandhada ayaa aad uga dheer tan bacda shaandhada, qiimaha dayactirkuna waa yar yahay.

2.Qaadashada habka nadiifinta ee saddex-goboleed ee horumarsan ee hadda jira (shaandhaynta, nadiifinta, static) si looga fogaado ifafaalaha "dib-u-qabsiga" inta lagu jiro nadiifinta, samaynta nadiifinta gebi ahaanba la isku halayn karo.

3.Naqshadeynta habka aruurinta boodhka ka hor, kaas oo aan kaliya ka adkaan cilladaha boodhka tooska ah oo si sahlan loo xidho kartoonka shaandhada, laakiin sidoo kale waxay si weyn u kordhin kartaa feejignaanta boodhka ee albaabka ururiyaha boodhka.

4. Qaybaha la soo dhoofiyo waxaa loo isticmaalaa qaybaha muhiimka ah ee saameeya waxqabadka ugu muhiimsan (sida pulse valve), iyo nolosha adeegga diaphragm ee qaybta nugul ayaa ka badan 1 milyan jeer.

5. Qaadashada tignoolajiyada buufinta iyo nadiifinta goonida ah, hal waalka garaaca wadnaha ayaa buufin kara hal saf isku mar (tirada kartoonada shaandhada ee saf kasta waa ilaa 12), taas oo aad u yareyn karta tirada valves-ka.

6. Habka nadiifinta dambaska saddex-goboleed ee waalka garaaca wadnaha wuxuu qaataa PLC kantarool toos ah, wuxuuna leeyahay laba nooc oo kontorool ah, waqti ama buug-gacmeed, oo laga doorto.

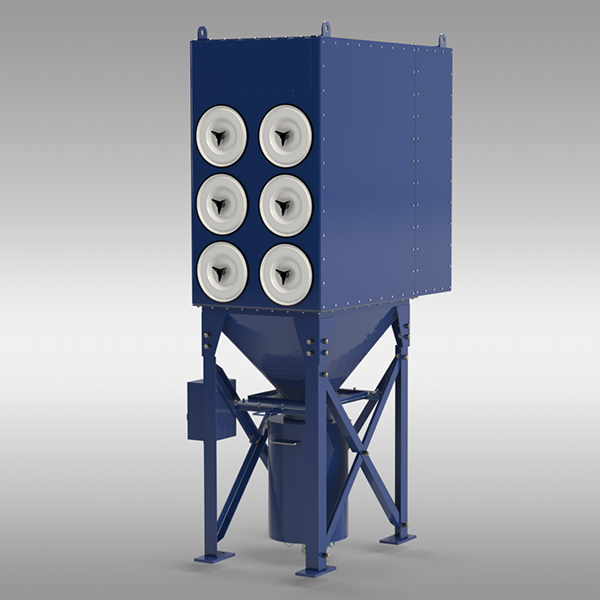

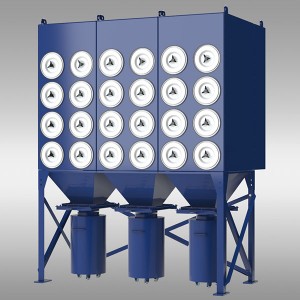

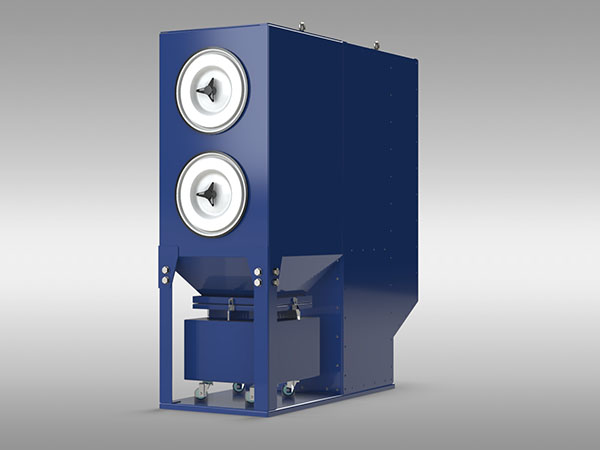

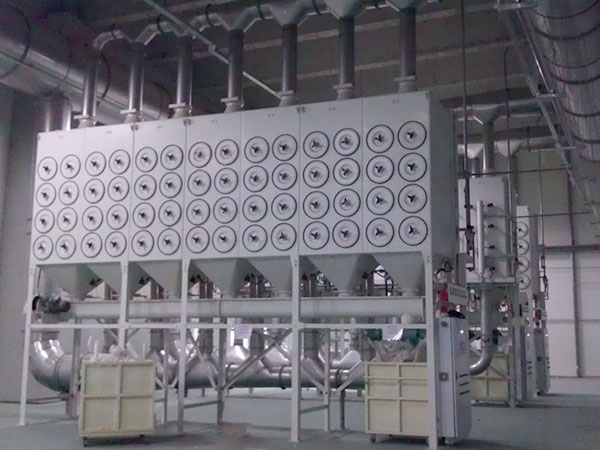

7. Isku-dar kasta oo kartridges filter ah oo leh tirooyin kala duwan oo tiirar iyo saf ah ayaa loo isticmaali karaa iyadoo loo eegayo baahida booska rakibaadda; meesha bannaan ee saddex-geesoodka ah ee ay ku jiraan aagga filter unug waa yar yahay, taas oo badbaadin karta kheyraad badan oo meel bannaan oo loogu talagalay isticmaalaha oo si aan toos ahayn u dhimi kara kharashka maalgashiga hal mar ah ee isticmaalaha.

8.Nolosha adeegga dheer, nolosha adeegga ee kartoonada shaandhada waxay gaari kartaa 2 ilaa 3 sano, taas oo si weyn u yaraynaysa tirada jeer ee walxaha shaandhada ee boodhka ururiyaha la beddelo (shaandhada bac dhaqameed ayaa la beddelaa 6dii biloodba mar celcelis ahaan), dayactirka waa sahlan tahay, dayactirkuna aad buu u yaraaday. Kharashka dayactirka isticmaalaha inta lagu jiro isticmaalka.

9.Alaabtan waxaa si weyn loogu isticmaalaa siigada warshadaha ee birta iyo birta birta, dhalaalidda non-ferrous, sibidhka dhismaha, tuurista makaanikada, warshadaha cuntada iyo iftiinka, warshadaha kiimikada maalinlaha ah, tubaakada, kaydinta kaydinta, kuleyliyaha saldhiga korontada warshadaha, kululeeyaha kululeeyaha, iyo qashinka degmada warshadaha guba. Sifaynta iyo maamulka.

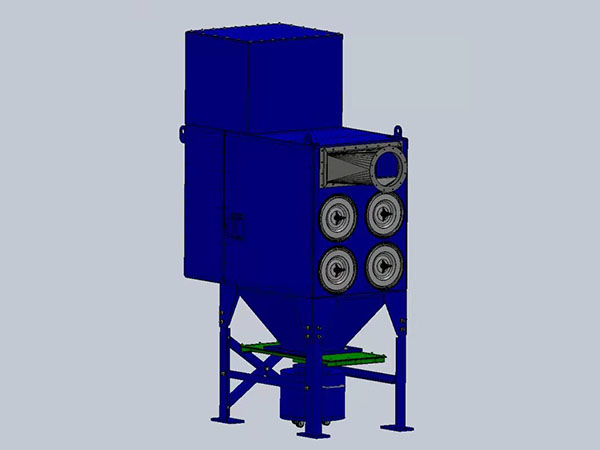

Qaab dhismeedka

Nooca kartoojku wuxuu ka kooban yahay tuubada hawada soo gelisa, tuubada qiiqa, jidhka sanduuqa, dambaska dambaska, qalabka nadiifinta dambaska, qalabka leexinta, saxanka qaybinta socodka hawada, kartridge filter iyo qalabka kontoroolka korantada, oo la mid ah sanduuqa garaaca garaaca wadnaha qaab dhismeedka ka qaadista. Habaynta kartridge-ka shaandhada ee boodhka ururiyaha waa mid aad muhiim u ah. Waxa loo habayn karaa si toosan saqafka sare ee golaha wasiirada ama waxa loo janjeedhin karaa xagga sare. Marka loo eego saameynta nadiifinta, habaynta toosan ayaa macquul ah. Qaybta hoose ee saqafka waa qolka shaandhada, qaybta sarena waa qolka garaaca wadnaha hawada. Saxanka hawo qaybinta ayaa lagu rakibay albaabka laga galo boodhka ururiyaha.

Mabda'a Shaqada

Ka dib marka gaaska ku jira boodhka uu galo boodhka boodhka ururiyaha, sababtoo ah balaadhinta lama filaanka ah ee socodka hawada ee isgoysyada iyo saamaynta saxanka qaybinta hawada, qayb ka mid ah qaybaha aan fiicneyn ee socodka hawada ayaa degaya dambaska. hopper ee hoos yimaada ficilka xoogag firfircoon; Qaybaha siigada ee cufan iyo cufnaanta hoose waxay galaan qolka shaandhada boodhka. Iyada oo loo marayo saamaynta isku dhafan ee faafinta Brownian iyo shaandheynta, boodhka ayaa lagu shubaa dusha sare ee walxaha shaandhada, gaaska la nadiifiyeyna wuxuu galaa qolka hawo nadiif ah waxaana ka siidaaya tuubada qiiqa iyada oo loo marayo marawaxad. Iska caabbinta filtarka kartoojku wuxuu kordhiyaa kororka dhumucda lakabka boodhka ee dusha sare ee walxaha shaandhada. Nadiifi boodhka marka iska caabintu gaadho qiimo cayiman. Waqtigan xaadirka ah, barnaamijka PLC ayaa xakameynaya furitaanka iyo xiritaanka valve garaaca wadnaha. Marka hore, waalka wiishashka qol-hoosaadku waa la xidhay si loo gooyo socodka hawada la sifeeyey, ka dibna waxa la furay valve electromagnetic. Hawada ciriiriga ah iyo wakhti gaaban ayaa si degdeg ah loogu ballaariyay sanduuqa sare waxaana lagu shubaa kartoonka shaandhada si ay u sameeyaan kartoonka shaandhada Balaadhinta iyo qallafsanaantu waxay soo saaraan gariir, iyo hoos ficilka socodka hawada ee soo noqnoqda, boodhka ku xiran dibadda dusha bacda shaandhada waa la diiray oo waxay ku dhacday hopper dambaska. Ka dib marka la dhammeeyo ka saarista boodhka, tuubada garaaca wadnaha ee elektromagnetic waa la xidhay, valve poppet waa la furay, qolkuna wuxuu ku soo noqdaa xaaladda shaandhaynta. Nadiifinta waxaa lagu sameeyaa qol kasta markeeda, wareegga nadiifinta wuxuu ka bilaabmaa nadiifinta qolka koowaad ilaa bilowga nadiifinta xigta. Boodhka dhacay wuxuu ku dhacaa hopper dambaska waxaana lagu sii daayaa tuubada dambaska ee dambaska.

Habka boorka ka saarida qashinka shaandhada shaandhada waa in marka hore la gooyo kanaalka hawada nadiifka ah ee qol gaar ah, oo qolka laga dhigo xaalad taagan, ka dibna la sameeyo garaaca garaaca hawada dib-u-qabashada si loo nadiifiyo boodhka, ka dibna dhowr ilbiriqsi ka dib ka saarista boodhka ka dib dejinta dabiiciga ah, kanaalka hawada nadiifka ah ee qolka ayaa mar kale la furay, taas oo aan nadiifin oo kaliya boodhka si buuxda, laakiin sidoo kale waxay ka fogaanaysaa boodhka labaad ee boodhka ay dhaliso buufinta iyo nadiifinta, si siigada ayaa qolba qol loogu wareegayaa.

Doorashada boodhka ururiyaha

1. Go'aaminta xawaaraha dabaysha sifaynta

Shaandhaynta xawaaraha dabayshu waa mid ka mid ah halbeegyada muhiimka ah ee xulashada boodhka ururinta. Waa in lagu go'aamiyaa iyadoo loo eegayo dabeecadda, cabbirka walxaha, heerkulka, xoojinta iyo arrimaha kale ee boodhka ama qiiqa codsiyada kala duwan. Guud ahaan, xoogga boodhka soo galku waa 15-30g/m3. Xawaaraha dabaysha shaandhaynta waa in aanu ka badnayn 0.6–0.8m/min; Xawaaraha dabayshu waa inuusan ka badnaan 0.8 ~ 1.2m/min; Xawaaraha dabaysha ee shaandhaynta waa in aanu ka badnayn 1.5-2m/min. Marka la soo koobo, marka la dooranayo xawaaraha dabaysha shaandhada, si loo yareeyo caabbinta qalabka, guud ahaan xawaaraha dabaysha shaandhada waa in aan la dooran mid aad u weyn.

2. Walxaha sifeeyo

Shaandheynta kartoonada JWST waxay qabataa PS ama PSU polymer-ka dahaarka leh ee shaandhada shaandhada. Marka gaaska la sifeeyay uu ku jiro heerkulka qolka ama ka hooseeyo 100°C, shayga shaandhada fiber-ka ee PS polymer-ka ah ayaa guud ahaan la isticmaalaa. Haddii loo isticmaalo codsiyada heerkulka sare, waa in la isticmaalo. PSU polymer-ka dahaarka leh ee shaandhada fiber-ka, haddii loo isticmaalo waqtiyo leh shuruudo gaar ah, waa in la sheegaa ka hor inta aan la dalban, iyo walxaha shaandhada waa in si gaar ah loo doortaa.

3.Foomka dheecaanka dambaska

Taxanaha JWST shaandheeyayaasha qashinka kartoonada dhamaan waxa ay adeegsadaan mareenada si ay u soo daadiyaan dambaska

Nidaamka soo kabashada walxaha filterku waa taageere fogeeya hawada ay ku jirto budada, ku shaandhaysa shaandhada hawada, ka dibna u adeegsata wareegga garaaca wadnaha si toos ah loo xakameeyo. Budada lagu dhejiyay walxaha shaandhada hawada inta lagu jiro buufinta budada ayaa lagu dumin doonaa socodka hawada sare.

Qaabka badeecada

JT-LT-4

JT-LT-8

JT-LT-12

JT-LT-18

JT-LT-24

JT-LT-32

JT-LT-36

JT-LT-48

JT-LT-60

JT-LT-64

JT-LT-112

JT-LT-160